Part 2: Implementing the home-repair programme

2.1

In this Part, we describe:

- why the home-repair programme was set up;

- the process for procuring a provider of project management services for the home-repair programme; and

- how the home-repair programme operates.

Summary of our findings

2.2

EQC's Board and Ministers decided on a home-repair programme because of its potential to contain inflation in the cost of repairs, ensure that funds were used for repairs, and maintain the quality of housing stock in Canterbury. Maintaining the quality of housing stock was considered important in encouraging people to stay in the region.

2.3

EQC's procurement of a project management provider to run the home-repair programme, Fletcher Construction, was done under the Government's emergency procurement guidelines. It was planned and carried out well.

Deciding to have a home-repair programme

The decision was made to set up a home-repair programme to reduce the risks of inflation in the cost of repairs and shortages of building materials.

2.4

After the 4 September 2010 earthquake, EQC's Board and Ministers agreed that, because of the scale of the earthquake, settling most claims in cash would not be appropriate. Instead, EQC would set up a home-repair programme to settle claims for damage that would cost between $10,000 and $100,000 to repair.

2.5

The decision to set up a home-repair programme enabled repairs to start as soon as possible and reduced risks. The identified risks were:

- the availability of building materials;

- cost inflation;

- the availability of skilled labour; and

- competition between organisations for labour and materials in Canterbury.

2.6

The home-repair procurement strategy identified that consistent repair standards would be an advantage of a home-repair programme. In turn, this would help reduce the risk of people leaving Canterbury.

2.7

The home-repair procurement strategy also identified that a managed home-repair programme could prioritise repairs based on need, ensure equitable access to repairs, and reduce the stress for homeowners of not being able to live or feel safe in their own home.

Procuring a provider of project management services

The home-repair programme was set up quickly and procured appropriately. Although EQC appropriately obtained independent and professional advice on the project management costs of shortlisted providers, doing so showed that determining what might be considered "reasonable" was challenging. In our view, this should have signalled for EQC the importance of ongoing scrutiny of project management costs.

2.8

To carry out a managed home-repair programme, EQC decided to set up a project management office (PMO) to co-ordinate and manage the large number of contractors that would repair thousands of homes. EQC knew that it did not have the resources or skills to do the project management work.

2.9

To procure those resources, EQC put together an evaluation panel of people who knew the market, including a senior procurement adviser seconded from the Ministry of Economic Development (now the Ministry of Business, Innovation and Employment, MBIE).

2.10

In our view, and based on our analysis of the contract for the home-repair programme and how it was procured, EQC planned and operated the procurement well.

An emergency procurement process

2.11

The procurement process was done under emergency procurement guidelines, based on advice from the former Ministry of Economic Development. This advice allowed direct sourcing of goods and services if open tendering resulted in unacceptable risks to people, property, or equipment, or unacceptable delays in re-establishing services.

2.12

The selected PMO needed to have the capacity to cope with the scale of repairs, the ability to expand operations to meet demand, and access to specialist advice.

2.13

EQC identified 14 organisations that could meet the requirements, after input from New Zealand Trade and Enterprise and the former Ministry of Economic Development. EQC issued the Request for Proposal (RFP) to the 14 organisations on 27 September 2010. After EQC advertised the RFP, one further organisation received a copy of the RFP document on 28 September 2010.

2.14

The RFP stated that the PMO was expected to provide several services, including:

- acting as a prime contractor (being a "one-stop shop for the management and delivery of reinstatement of properties");

- sourcing, subcontracting, and managing a number and range of skilled contractors;

- ensuring a single point of contact for stakeholders (including homeowners);

- developing an approved pricing mechanism;

- providing adequate reporting to EQC; and

- managing the programme of repairs for all accepted EQC residential claims.

2.15

Respondents to the RFP had to address several risks, including repair priorities based on need, effective management of the cost of repairs, ensuring that the quality of repairs met the required standards, and the effective management of conflicts of interests.

Evaluating the tenders

2.16

The evaluation panel selected a shortlist of two, using criteria and weightings of:

- capacity to deliver (35%);

- capability and experience (25%);

- method (25%); and

- cost and approach (15%).

2.17

The weightings reflected the overall priority of getting the repairs done. Capacity and capability were given greater weight than cost and approach.

2.18

To gain assurance on the procurement process followed in shortlisting two companies, the Chairperson and Deputy Chairperson of EQC's Board interviewed the evaluation panel before reporting to EQC's Board. EQC's Board approved the shortlist.

Review of shortlisted proposals

2.19

EQC commissioned two independent quantity surveying firms to assess the costs of the two shortlisted proposals.

2.20

The independent quantity surveying firms commented on the reasonableness of the proposed costs of providing PMO services. They both concluded that the cost of the two proposals was reasonable and in line with industry standards.

2.21

The firms reached different conclusions about the costs of each proposal, and different conclusions about which proposal would be more expensive. The differences in assessed costs were tens of millions of dollars.

2.22

This shows that assessing the reasonableness of the costs was challenging and that the professional judgement of what was reasonable and in line with industry standards varied widely.

2.23

A firm of Chartered Accountants reviewed the financial status of the shortlisted companies and supplied a report to EQC on 14 October 2010. The report did not indicate any financial capability or solvency matters with either of the shortlisted companies.

Decision

2.24

Fletcher Construction was identified as the preferred supplier of PMO services. A recommendation to award Fletcher Construction the contract for PMO services was submitted to EQC's Board on 14 October 2010 and approved.

2.25

EQC entered a Memorandum of Understanding (MoU) with Fletcher Construction on 22 October 2010. A PMO Services Agreement between the parties replaced the MoU on 6 July 2011. The decision to have an MoU first was deliberate. It enabled repairs to start quickly while the contract was negotiated. It also gave both parties the opportunity to learn more about the challenges of managing home repairs.

2.26

EQC commissioned an external report on the probity of the procurement process. The report, completed in December 2010, concluded that the RFP process was consistent with good practice, based on probity principles. The report also said that EQC identified and mitigated potential probity risks.

Respective responsibilities of EQC and Fletcher Construction

2.27

A Project Control Group (PCG) governs the PMO contract. The PCG consists of senior representatives from both parties, with an EQC representative as chairperson. It oversees all aspects of the home-repair programme, to ensure that the project goal is achieved and potential issues within the home-repair programme are identified and resolved. The project goal is that:

… [all repairs] are completed properly, safely, as quickly as practicable and in a manner that provides value for money in the circumstances.

2.28

The contract requires Fletcher Construction to act as EQC's agent in settling claims through repairing earthquake-damaged houses. However, EQC is under no obligation to pass any claim for repair to Fletcher Construction.

2.29

Under the contract, Fletcher Construction is required to prepare and manage an accreditation process for contractors and consultants appointed to carry out repairs. EQC needs to approve the accreditation process and any changes to the process. This process has been prepared. Fletcher Construction is also responsible for contracting with contractors and consultants on EQC's behalf (on terms approved by EQC) and for monitoring contractors and consultants.

2.30

A similar process for merchants was anticipated in the contract. Accredited merchants were to supply all materials used in the home-repair programme. The standard building contract used in the home-repair programme requires tradespeople to use accredited merchants. Six building material supply chains and three paint supply chains have been accredited to the home-repair programme.

2.31

Fletcher Construction is required to prepare and maintain a contractor-pricing schedule (known as a rates ceiling schedule). The rates ceiling schedule, which has been prepared, includes the cost of materials, installation, labour, and management. In preparing the rates ceiling schedule, Fletcher Construction is required to liaise with EQC and set the maximum price that EQC is willing to pay for repairs. Fletcher Construction needs EQC's approval for the rates ceiling schedule and any changes to it.

2.32

The total cost to EQC for the PMO services from Fletcher Construction is a margin on the direct repair cost plus the salaries and wages of Fletcher Construction staff who work on the project, with a multiplier on these salaries and wages. The multiplier covers the additional costs of employing staff, including leave and Accident Compensation Corporation levies. It is a cost-recovery mechanism. EQC also reimburses the direct project management costs such as rent, computers, and other equipment used by Fletcher Construction.

How the home-repair programme works in practice

Repairs have been managed through repair hubs located throughout earthquake-damaged suburbs. Although there was a clear rationale for widely located repair hubs, this approach can be expensive and needs to be carefully managed. Bringing the completion date forward by a year could remove considerable fixed costs from the home-repair programme.

Damage covered by the home-repair programme

2.33

Originally, the scope of the home-repair programme was for repairs to houses that had between $10,000 and $100,000 worth of non-structural earthquake damage, and all houses with structural damage of less than $100,000.

2.34

Figure 1 shows the number of insured properties that were damaged in the Canterbury earthquakes by the value of the damage and whether they will be part of the home-repair programme or settled in cash. Usually, houses with less than $15,000 in damage are settled in cash.

Figure 1

Number of repairs, by value of damage, at 22 July 2013

Note: The cost categories were provided by EQC. Normally, the home-repair programme covers houses with between $15,000 and $100,000 in damage. Some homes were repaired before the threshold for cash-settling increased to $15,000, and some homeowners asked EQC to manage their repairs instead of receiving a cash settlement. Some houses in the home-repair programme have suffered smaller amounts of damage attributed to separate earthquakes which, in total, amount to more than $100,000.

2.35

The threshold changed in July 2012 from cash-settling claims below $10,000 to cash-settling claims below $15,000. This decreased the number of repairs in the programme by about 8500 houses.

2.36

After scoping work, the cost to repair some houses is found to exceed $100,000 so the claim passes to the homeowners' insurance company. Some homeowners decide to opt out of the home-repair programme part-way through. In these instances, the houses are not counted as completed repairs even though they have used programme resources. To July 2013, about 14,000 houses were in these two categories.

Repair hub structure

2.37

During our audit, the home-repair programme was delivered through 20 offices (known as hubs, see Figure 2) with their own defined areas. There were also two specialist hubs; one for engineering and technical expertise, and another for urgent response work. A central office, known as "EQR (Earthquake Recovery) Command Central", manages the hubs.

2.38

To manage repairs within its area, each of the 20 hubs has a mixture of Fletcher Construction and EQC staff. There can be between eight and 35 Fletcher Construction staff, and up to four EQC staff, in each hub. Fletcher Construction told us that there has never been a construction project in New Zealand with such a concentrated "branch office" structure employing so many people.

2.39

The reasons for a widely dispersed hub structure were the need to have a "community footprint", be seen to be taking action, accommodate up to 700 staff (commercial premises were scarce after the earthquakes), and enable liaison with local communities.

Figure 2

Picture of a typical repair hub

2.40

At the beginning of 2013, the home-repair programme was expected to involve:

- up to about 700 staff working for Fletcher Construction;

- about 70 staff from EQC working in the hubs; and

- more than 1000 contractors accredited to the programme.

2.41

During our audit, EQC brought forward the completion date for the programme from the end of 2015 to the end of 2014. The revised targets for the home-repair programme were to finish repairs of homes with structural earthquake damage worth more than $50,000 by the end of 2013 and all other repairs by the end of 2014.

The home-repair programme process

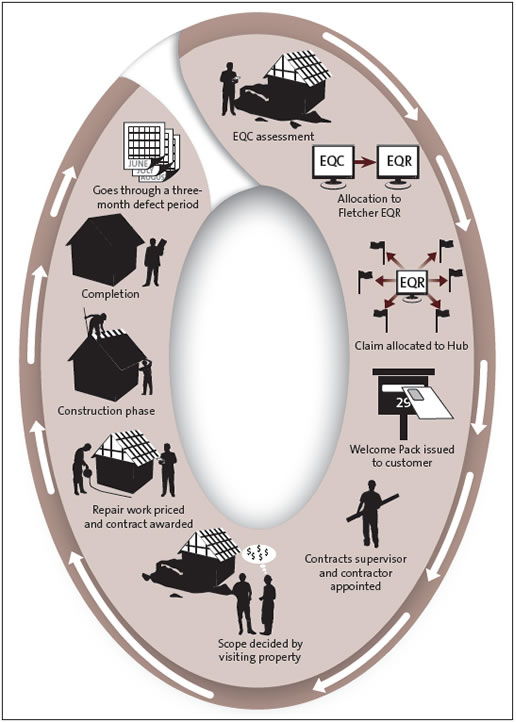

2.42

Figure 3 sets out a high-level overview of the home-repair process. Appendix 1 explains each of the steps in the home-repair process further.

Figure 3

How the home-repair programme operates

Source: Based on EQC's depiction in Your guide to the Canterbury Home Repair Programme (August 2012). "Fletcher EQR" refers to the business unit of Fletcher Construction Limited that was set up to provide PMO services to EQC. We use the term "Fletcher Construction" to refer to that business unit.

page top